Scrubbers from INDUSCO Environmental are designed for applications requiring the removal of a wide range of various types of contaminants from various types of gas streams. Typical applications for contaminant removal include noxious or toxic fumes from all types of chemical process operations or odorous fumes from industrial processes, wastewater, sewage treatment, and compost facilities.

Materials of Construction include Carbon steel, Stainless steel, Hastalloy, AL6XN, FRP (Fiberglass Reinforced Plastic), Thermoplastics, or Dual-laminates. Each scrubber system is individually designed and fabricated for each unique requirement.

INDUSCO Environmental packed bed scrubbers are designed for applications requiring the removal of a wide range of various types of contaminants from various types of gas streams. Typical applications for contaminant removal include noxious or toxic fumes from all types of chemical process operations or odorous fumes from water/sewage treatment and compost facilities.

Depending upon each application, scrubbers can be manufactured from metal materials, fiberglass reinforced plastic (FRP), thermoplastics, or dual-laminates. Each scrubber application is individually designed and engineered for each unique requirement.

Many scrubber units help companies comply with emission control for EPA regulations or preserve the quality of the environment for workers and the community. To remove the unwanted elements, contaminated air is passed through the scrubber using either positive or negative pressure, created from a fan either upstream or downstream from the scrubber unit.

The gas stream enters the scrubber unit near the bottom, travels up through the packed bed section, and is vigorously exposed to the scrubber solution through a demister assembly. It is discharged either to the atmosphere or routed back through the original process.

To provide the most economical solution for our client’s scrubber needs we take into account the volume of gas to be treated, type and concentration of contaminants, and the required discharge limits, in determining the best solution for your needs. INDUSCO Environmental engineers will work closely with you to design the system that will best fit your needs.

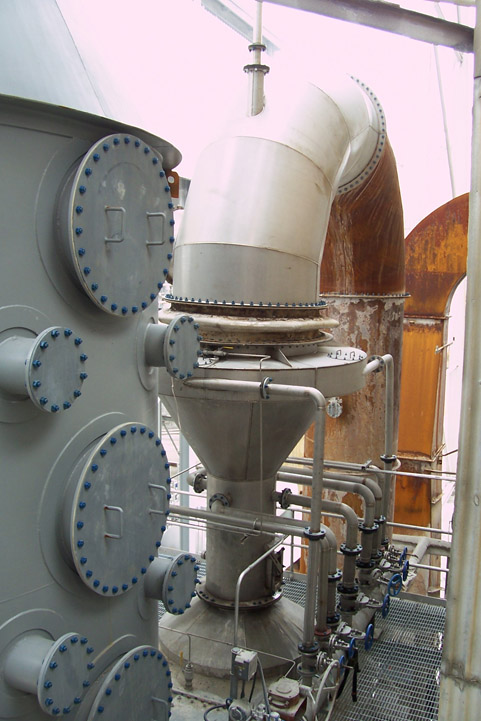

The INDUSCO Environmental Venturi Scrubber is designed to remove particles, as small as 1 micron, from gas streams. Particulate removal is accomplished by contacting the particulate-laden gas stream with a scrubbing liquid, most commonly water.

The gas stream is directed through the scrubbing liquid, next through the throat (a smaller diameter connection between the Venturi and the separator) of the Venturi, and finally through a cyclonic separator, which creates a significant, designed drop in pressure where the particulate matter is removed from the gas stream. The cleaned gas exits the separator and the liquid is returned to the sump reservoir for recycling. Extremely high particulate removal efficiencies are obtained using this technique.

The two main types of scrubbers are wet scrubbers and dry scrubbers. These scrubbers can reduce up to 90% of emissions that contribute to smog and acid rain. Wet scrubbers are effective air pollution control devices for removing particles or gases from industrial exhaust streams.

Pre-Packaged Modular Scrubber systems are offered as a single or multi-stage units. Each system is designed for the particular application and supplied with an integral liquid sump, liquid recycle pump(s), liquid recycles piping, valves, instruments, and control panel. The prepackaged unit provides a simple plug and play design features to make the installation as quick and efficient as possible.

These types of units are great for areas where installation space is a premium. Unique features include the ability to incorporate multi-chemistries in separate liquid sumps for the best multi-stage scrubber system benefits.

Packaged modular scrubbers can accommodate any of your scrubbing and absorption requirements.

Crossflow Scrubber moves contaminated air horizontally through a packed bed and the irrigation process flows down vertically through the packing media for a flexible and efficient removal of various types of contaminants from gas streams.

Crossflow Scrubbers can be very effective especially when using a caustic solution to scrub an acid gas. When faced with space restrictions the horizontal design combined with lower pressure drops and higher capacities make the Crossflow Scrubber a desirable option.

Fume Scrubbers are designed to remove contaminants from an air stream by using intimate contact between the airstream and a liquid “scrubbing” solution. The airstream enters the scrubber near the bottom and progresses up, counter-currently, through a “packed bed” and is discharged through the top of the scrubber.

Scrubbing liquid is distributed across the top of the packed bed section by either a spray or a distribution trough assembly. A demister is installed near the top of the scrubber, to remove as much of the liquid from the airstream as possible prior to discharge into the atmosphere.

Common Fume Scrubbers are Hydrogen Sulfide Scrubber, Hydrogen Chloride Scrubber, Hydrogen Fluoride Scrubber, Sulfur Dioxide Scrubber, and Sulfur Trioxide Scrubber.

INDUSCO Environmental manufactures a variety of

application-specific scrubbers based on our client’s needs:

Air Scrubber – Chemical Scrubber – Scrubbers – Air Pollution Control Scrubber – Ammonia Scrubber – Carbon Scrubber – Caustic Scrubber

Chemical Scrubber Odor Control System – Chemical Process Scrubber – Chlorine Scrubber

Crossflow Scrubber – Fume Scrubber – Gas Scrubber – H2S Scrubber- HCL Scrubber

HF Scrubber Horizontal Packed Bed Scrubber – Impingement Scrubber – Modular Scrubber

Nitrous Oxide Scrubber Odor Control Scrubber – Packed Column Scrubber – Packed Bed Scrubber

Particulate Scrubber – Pre-Packaged Scrubber – Sulfuric Acid Scrubber – Sulfur Dioxide Scrubber

Three Stage Scrubber – Two Stage Scrubber – Venturi Scrubber – Vertical

Packed Bed Scrubber – Wet Scrubber – Water Jet Scrubber – Wet Packed Bed Scrubber

"*" indicates required fields

Your trusted partner for high-quality, custom air pollution control and chemical process equipment.